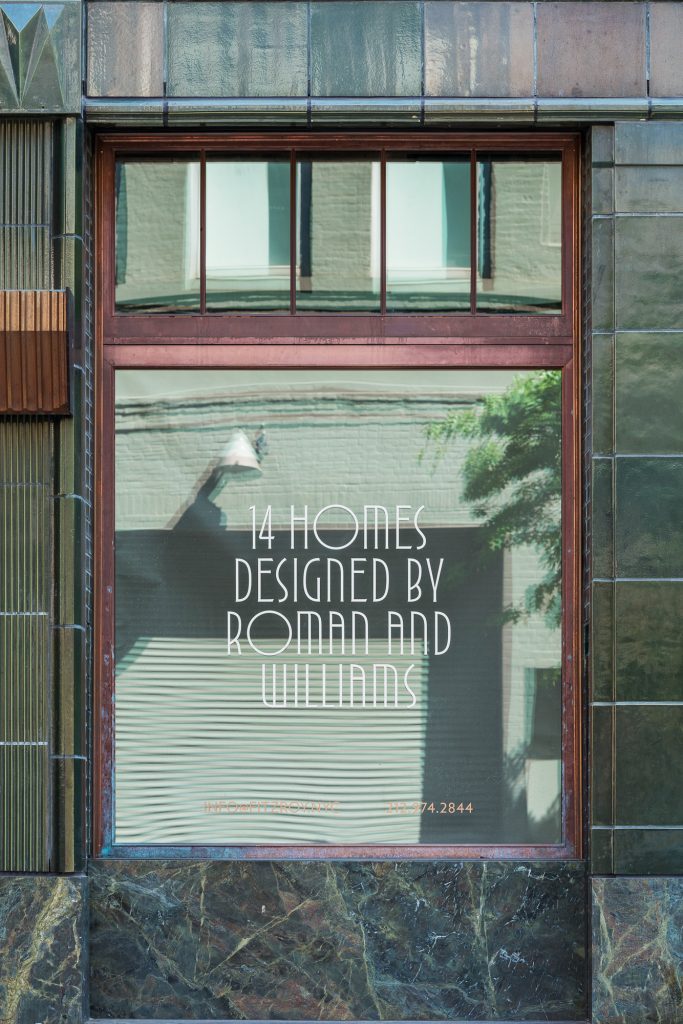

The Fitzroy West 24th Street, located within reach of the iconic Highline, is a striking residential building featuring a terra cotta facade and Open Architectural custom copper-clad oak windows. This building is a collaborative effort between legendary design team Roman and Williams and developers JDS Development Group. The striking copper-clad oak windows bring the building’s façade to life. This large-scale project boasts over (200) custom copper clad windows, and numerous other copper finishes. The beautiful copper windows do not sacrifice function. The double and triple glazed glass and superior installation ensures that the windows are soundproofed from the busy exterior, and allow for energy efficient heating and cooling.

| Architect: The Vilnits Group |

| Location: New York, NY |

| Area: 7733 sq.ft |

| Year of completion: 2019 |

At Open Architectural Windows and Doors, we approach each luxury project as a unique opportunity to merge innovation with artisanal detail. Our work on a beautiful, high-end building on West 24th Street, in Manhattan’s Chelsea neighborhood, reflects a deeply customized, materials-driven process—where copper, wood, and fine craftsmanship converge to support a remarkable architectural vision.

The building’s windows and doors were developed using traditional profiled systems that recall historic European architecture. Each unit was made of wood and finished with copper cladding. We chose copper for its aging properties and rich texture. The architect envisioned a harmonious facade of mixed materials. Green ceramic tiles would complement the copper window elements. The copper evolves time, developing a greenish patina as a result of exposure to weather, moisture, and sunlight. Every piece of copper cladding will age differently as the green patina develops, turning the facade into an ever-evolving, one-of-a-kind feature that reveals an ever-deepening interplay of textures.

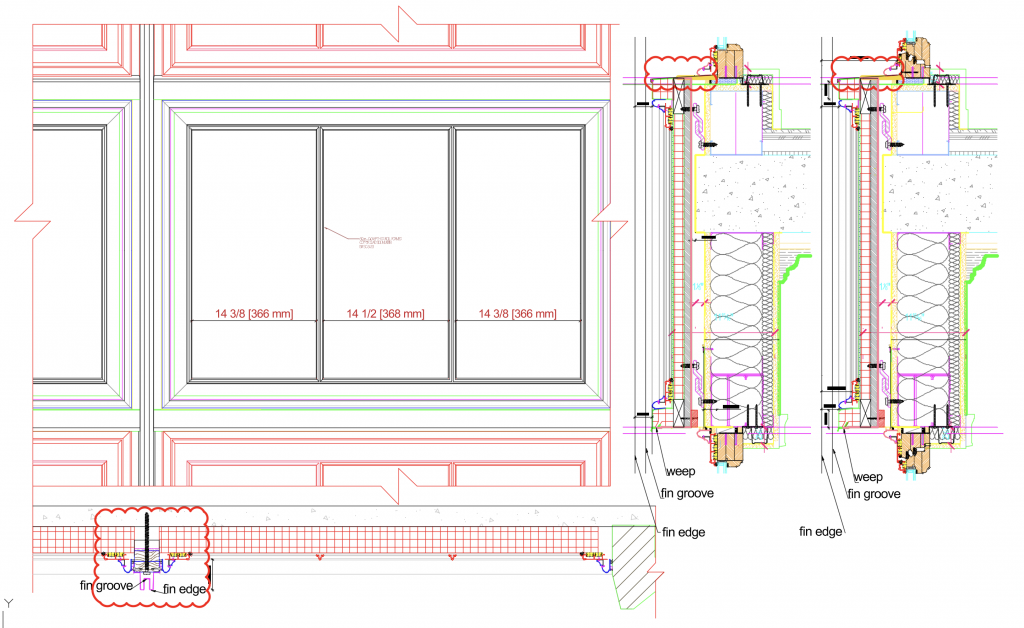

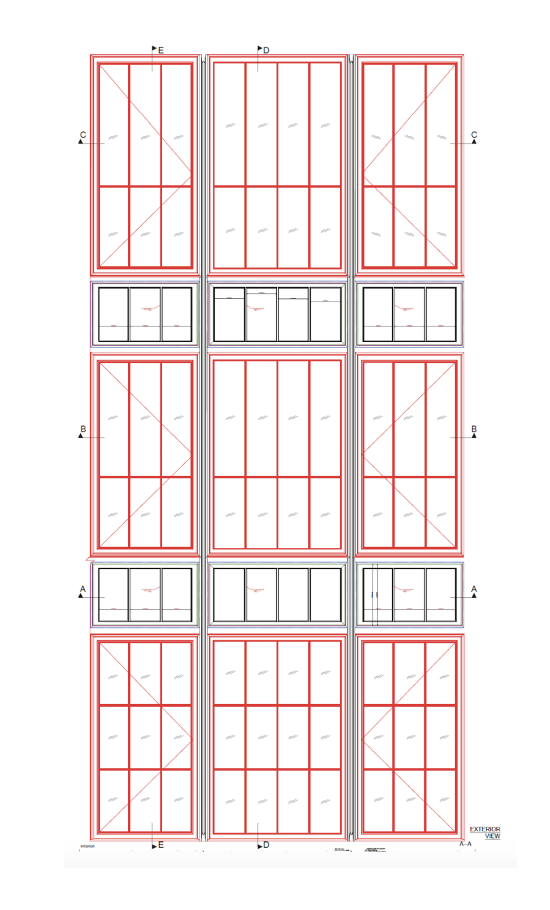

The entire building was meticulously modeled in 3D by the architectural team at Roman and Williams, who conceived every element—from the custom copper panels down to individual bricks—with sculptural intent. This high-resolution model guided our production process, enabling us to fabricate systems with all of the necessary dimensions, geometry, and transitions.

Our team worked from this architectural model to ensure the seamless integration of the windows, copper spandrels, and trim components, preserving uniformity across the entire building.

To maintain continuity across the facade, we created custom-made vertical elements that joined window units to the copper panels. These components were made to precise shape and aligned with adjacent fenestration systems, allowing for unbroken visual transitions across structural joints. The interplay between straight lines and sculpted detail became a defining feature of the project.

One of the key challenges we faced was developing a durable copper plating solution for the custom bronze profiles.

Given that copper is a soft material, so we needed to strengthen it without losing its look. We used a bronze alloy with a thin copper plating, just a few micrometers thick. This gave the structure durability while keeping the architect’s vision intact.

Many windows were outfitted with grilles, and connected directly to architectural panels. We fabricated a significant number of brickmolds, trim elements, and decorative transitions on-site to ensure that each component was perfectly integrated into the aligned with the facade.

As the years pass, copper develops a natural patina. Where rainwater comes into contact with the metal, the patina deepens to a rich green; where shielded, the copper retains its warm, golden hue. The result is a building that visually transforms with time, never static, always evolving.

On the rear elevations, we designed a pair of walkable skylights, seamlessly integrated into the roof. These units underwent thorough field testing to ensure durability, watertightness, and energy performance. Inside, the project was completed with premium trim hardware by Nanz—distinctive handles and mechanisms that match the building’s unique design.

At the Fitzroy , every detail mattered—from the finish of a handle to the angle of a mullion. All window types were thoroughly tested and subsequently passed all of the tests required by New York City regulations. This unique project shows our skill in blending modern methods with timeless materials. The result is a building that feels distinct and will evolve into a lasting part of New York City’s landscape.