Cooperstown, NY, a small town located just under 150 miles north of New York City. Most people will know it only as home to the National Baseball Hall of Fame and Museum. Situated at the foot of the Otsego Lake, Cooperstown is an historical colonial town that is doing some modernizing of its own. We were pleasantly to work on a project with a local homeowner. He wanted contemporary, aluminum-clad windows and doors featuring stained white-oak interiors for their home. When we learned more about the homeowner and architect’s plans, we were very excited to join the project.

For this project, we very pleased to work alongside with our Sales Engineer, Guy Messier, a window and door expert with over 15 years’ worth of experience in the industry. Through Guy, we were introduced to I-Kanda, a Boston-based firm that we have long admired. Sangsuri Chung, one of their project managers, worked on this one with us. The General Contractor was Will Dykstra, of Dykstra Construction, a local company.

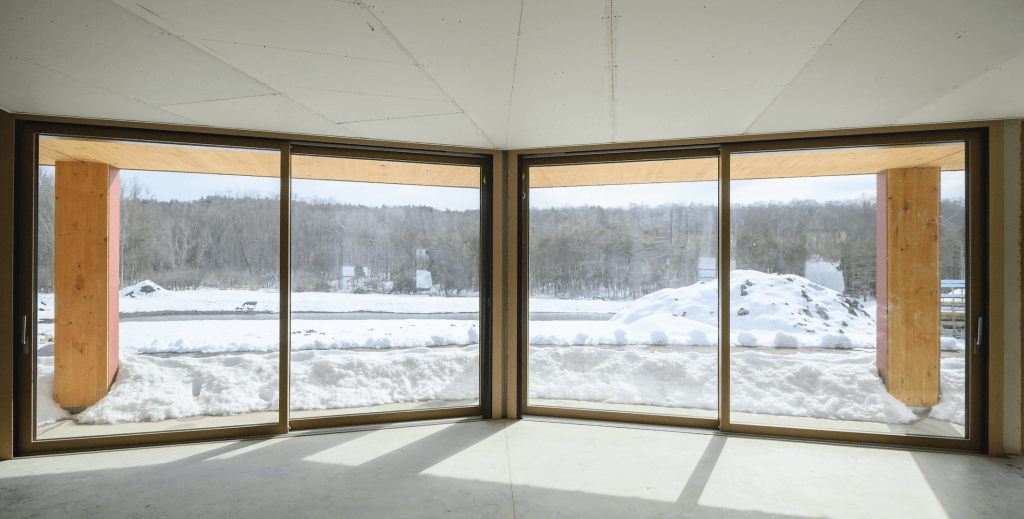

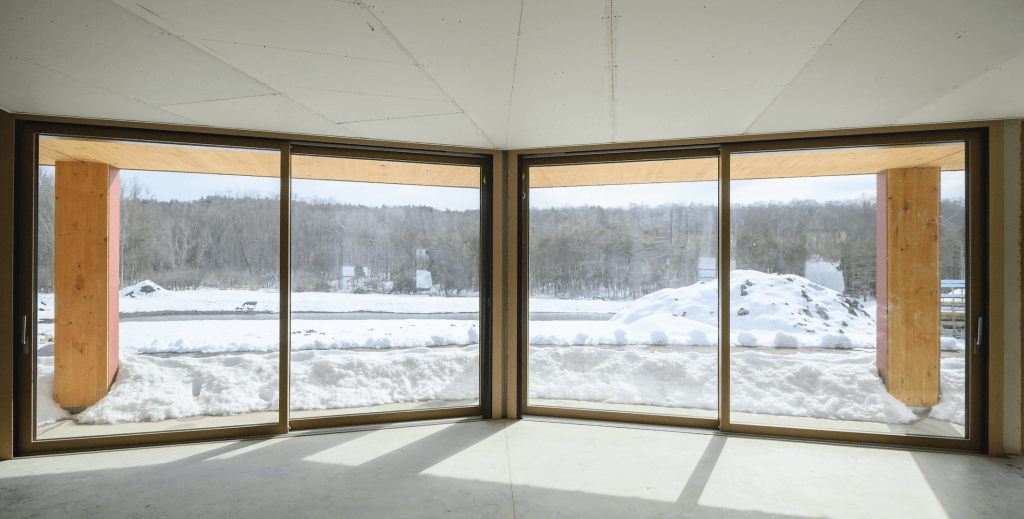

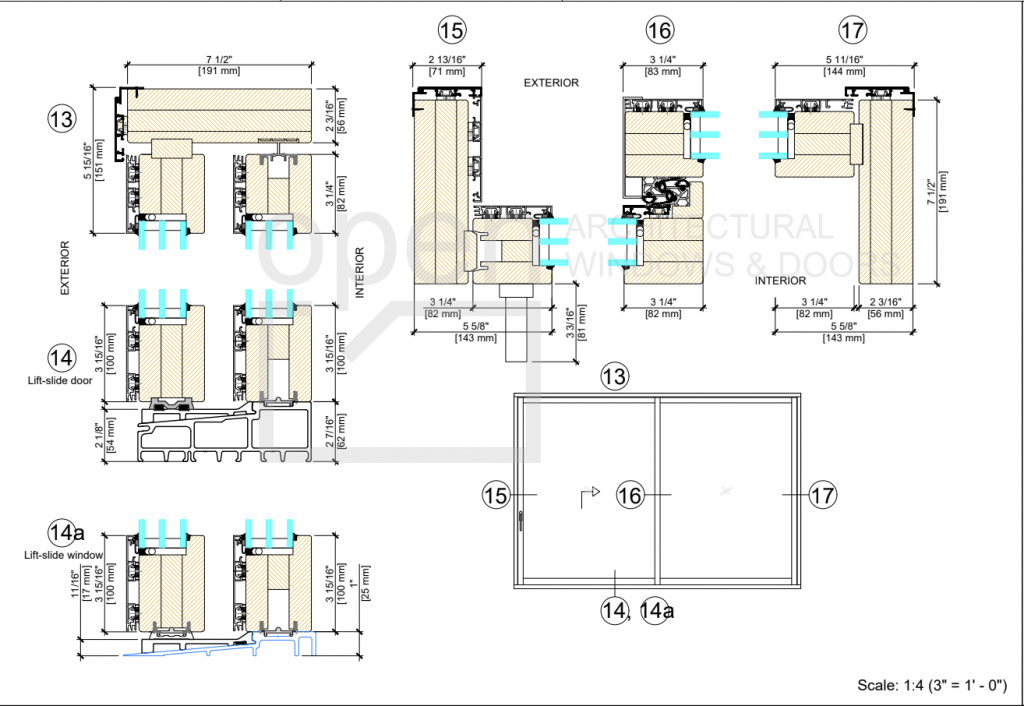

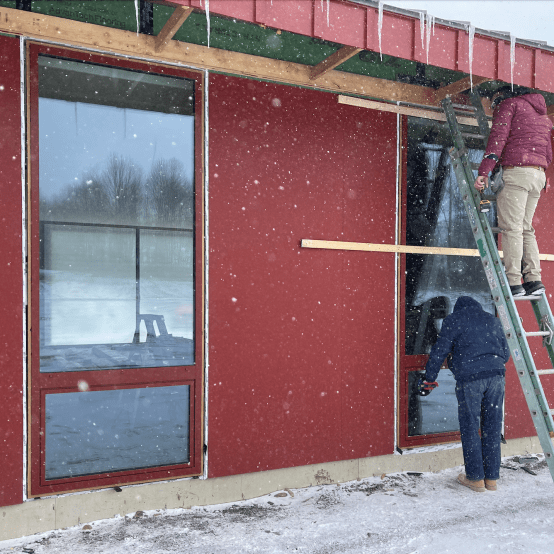

The architect and homeowner’s vision were very unique and exciting so it was a really special project to work on. They wanted to design a minimalist, large, open-plan home with high ceilings to maximize light and space. While the house was not designed to be Passive House certified, they wanted to make it as comfortable, durable, and energy efficient as possible. Especially when you take the cold Cooperstown winters into consideration. The overhanging roof (pictured) offers shade also from the sun in summer. It has the added benefit of keeping the house clear of snow in winter. As it’s the homeowner’s primary residence, they wanted to invest in long-term comfort so, for a number of related reasons, they went with triple-glazed windows and doors.

After learning more about the plans, together with the design-build team, we immediately set to work on our proposal. After much deliberation and consultation with us, the homeowner and architect decided that powder-coated aluminum-clad windows and doors would best suit the project. The homeowner opted for red cladding to match the building’s exterior, and stained white oak for the interior. They wanted the reduced maintenance of aluminum-clad windows and with all of the warmth and feel of white oak wood on the interior. The white oak was finished to match the home’s custom cabinetry and other millwork. The architect chose the distinct red color for the building and cladding as an aesthetic reference to the traditional red barns commonly seen around Cooperstown and other rural areas in New York State.

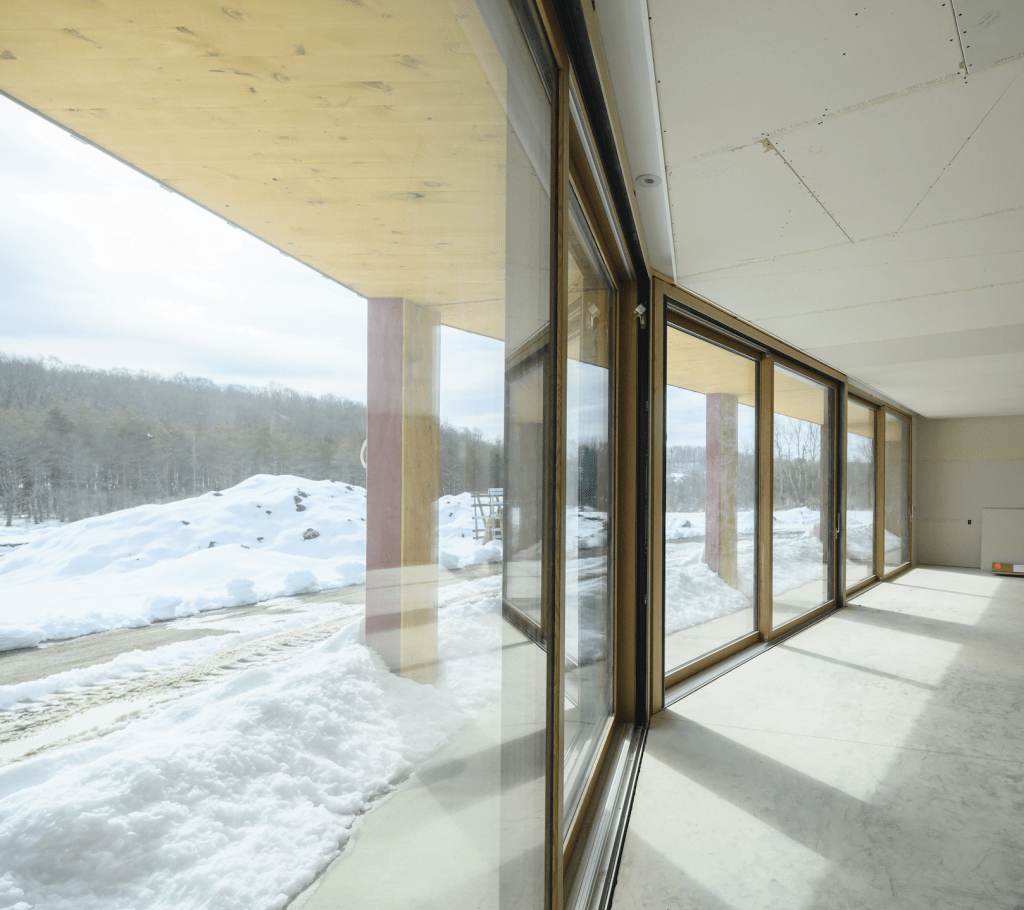

Undoubtedly, the most exciting and challenging part of the project was designing the three two-panel lift-slide door units with integral retractable screens. Each triple-glazed lift and slide sash weighs 840lb is 7.5ft wide x 10ft high.

Typically, European-designed tilt and turn windows have wide, or what we often like to call “heavy,” sight lines. With this project, however, we–along with the client and the design-build team–wanted something slimmer.

With that in mind, Open AWD developed a reduced-sightline aluminum-clad system with all of the well-known benefits (strength, security, and durability) of European-style aluminum-clad systems. Even with the size of the doors, we were able to design the doors with center mullions of just 3 ¼ inches (82mm). We used this custom system for the fixed and operable windows, also.

With Open’s heavy duty lift and slide roller system, even doors with 72 sq. ft. of triple glazing, operate smoothly and easily. Lift and slide door hardware lifts the sash a quarter inch off the tracks, and disengage the weather stripping, so the doors roll easily.

The beautiful ash wood cabinetry was crafted by Geoffrey T. Foster. It perfectly complemented the white oak window frames.

The client requested insect screens for the lift-slide doors. Open proposed a retractable insect screen that would be integrated and concealed within the opening. The frame of the insect screen was designed bo be concealed by interior trim work. The oversized insect screen had to be especially created for the house. You can watch a short video of Andrew, one of our project managers, demonstrating how to operate it.

As with any projects featuring oversized units, delivery requires extra thought, care, and preparation. As the units were so large, we needed to consider how to safely deliver the the units to the job site. This included very basic but important considerations such as finding a truck large enough to transport the units, and for this project with a deck low enough to navigate low clearance areas (low bridges; power-lines; trees etc), as well as having the proper equipment at the job site to unload safely and securely. We used a lowboy trailer to transport the units to the job site in Upstate New York.

Once the licensed and certified installation team we work with, unloaded the units, they began installing.

The installation team used a vacuum glass manipulator to unload and move the windows and doors to their openings. From there, the installers prepared the openings and installed the frames before finally installing the sashes.

A video below shows the manipulator being used to move one of the lift-slide door sashes. A few more pictures of the installation process are shown below.

If you have a project in mind and would like to learn more about Open Architectural Windows and Doors’ products and capabilities, please contact us at 929-202-2558. Alternatively, you can email us here and one of our project managers would be happy to talk through your plans and ideas together with you.

OPEN Architectural Windows and Doors: Proudly making your architectural dreams a reality for over a decade.