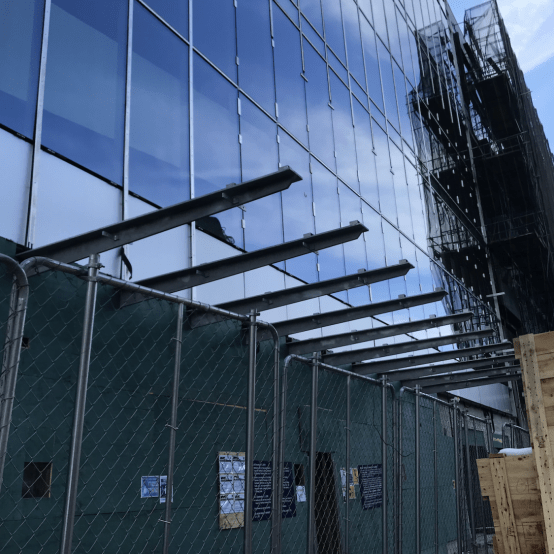

In 2019, Open Architectural Windows and Doors was contacted by a team of architects to design a curtain wall system, as well as windows and doors, for a project in Manhattan. The project, which consisted of 15,000 sq ft of glass, was for a car showroom. We had completed a wide range of commercial, residential, and high-value projects before, but never a car showroom. After we met with the client and got a better understanding of what they were looking for, we were very excited to join the project.

Choosing The Perfect Showroom Windows

When we first met with the client, they had originally been looking for an aluminum curtain-wall system. Aluminum systems are relatively common for showrooms. However, because the showroom was located at the edge of Manhattan close to the water, it was subject to more stringent guidelines. New York City has specific guidelines governing a structure’s capacity to withstand high winds.

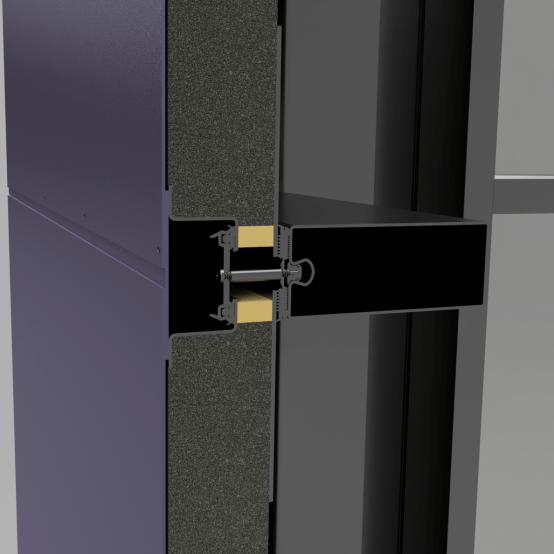

While aluminum could be used for a project like this, it would not be possible to achieve the kind of slim profiles that would be possible if steel were used. For example, you might need a mullion with a depth of up to 12 inches to ensure that it is able to securely keep the IGUs in place. Even at that, aluminum would require steel reinforcements inside the mullion to provide the requisite strength. It would take far bigger and thicker aluminum mullions to keep the IGUs in place. In that sense, slim profiles are not easily attainable with aluminum.

Steel, on the other hand, is much stronger, and provides a wider range of possibilities. This becomes an important issue in projects where oversized IGUs (or jumbo glass) is used. The main challenge we had to overcome was achieving the requisite mullion strength in order to hold the IGUs in place and withstand high wind load. We were able to use 6 inch deep profiles for vertical spans of up to 24 feet.

After much discussion, our client was very pleased to go forward with a steel curtain wall system. In addition to this, they asked us to design all of the metal paneling around the showroom as well as two custom-made awnings for above the doors. Once the steel for the curtain wall went into production, we began finalizing the oversized IGUs.

What Are Oversized IGUs or Jumbo Glass?

Oversized IGUs, also known as jumbo glass, are simply IGUs which are larger than standard-sized IGUs.

They are often used in buildings with modern designs or in retail spaces, such as shops, museums, and showrooms because they offer better, uninterrupted views.

They provide greater freedom for the architect, far more natural light, as well as a greater sense of openness within a space. This is why they they are standard in modern showrooms.

On the technical side of things, oversized IGUs provide a greater degree of thermal resistance than standard-sized windows.

Larger IGUs mean fewer joints and weak spots (which allow heat to pass through). This means greater thermal efficiency and maximum comfort.

Oversized IGUs make it easier for the architect to achieve clean, beautiful lines within the overall design. While they also create more opportunity for exposure to sunlight, any unwanted heat gain can easily be avoided by adding coatings, such as Low-E. This also controls any glare from sunlight.

While oversized IGUs are very visually impressive, they come with certain challenges and considerations. One of the most important is wind load. In our case, we worked closely with the engineer to determine the exact thickness to withstand high wind loads. We settled on 1/2 inch thickness, in certain areas, for the outside glass.

As of today, the largest IGUs produced in Germany are in sizes of up to 10.5ft x 61ft. Increasingly, more customers are requesting oversized IGUs for their projects. For more information on this, see our last article on them.

Designing The Showroom’s Awning and Paneling

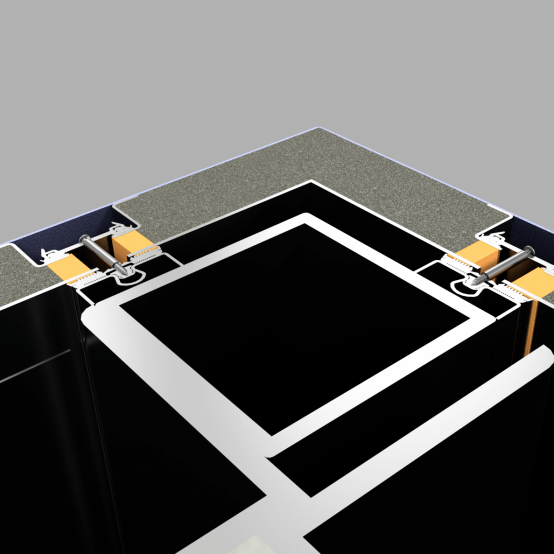

The architect also asked us to design two awnings as well as the exterior paneling to complement the showroom. Undoubtedly, designing the two awnings made for some of the most interesting work on this project. As you can see below, we decided on a large pane of specially-designed tempered and laminated safety glass above each door. This ensured it could withstand wind-loads as well as any other unexpected loads, such as heavy snow. Encased in a steel frame, the canopy was a striking addition to the project. We used stainless steel spider fittings to hold in place each panel of glass.

To design the metal paneling you can see around the building, we spent hundreds of hours researching and mocking up samples. We used 3D modeling software to arrive at the exact look we wanted for the panels. You can view some of the drawings as well as the final product below.

Installing The Glass

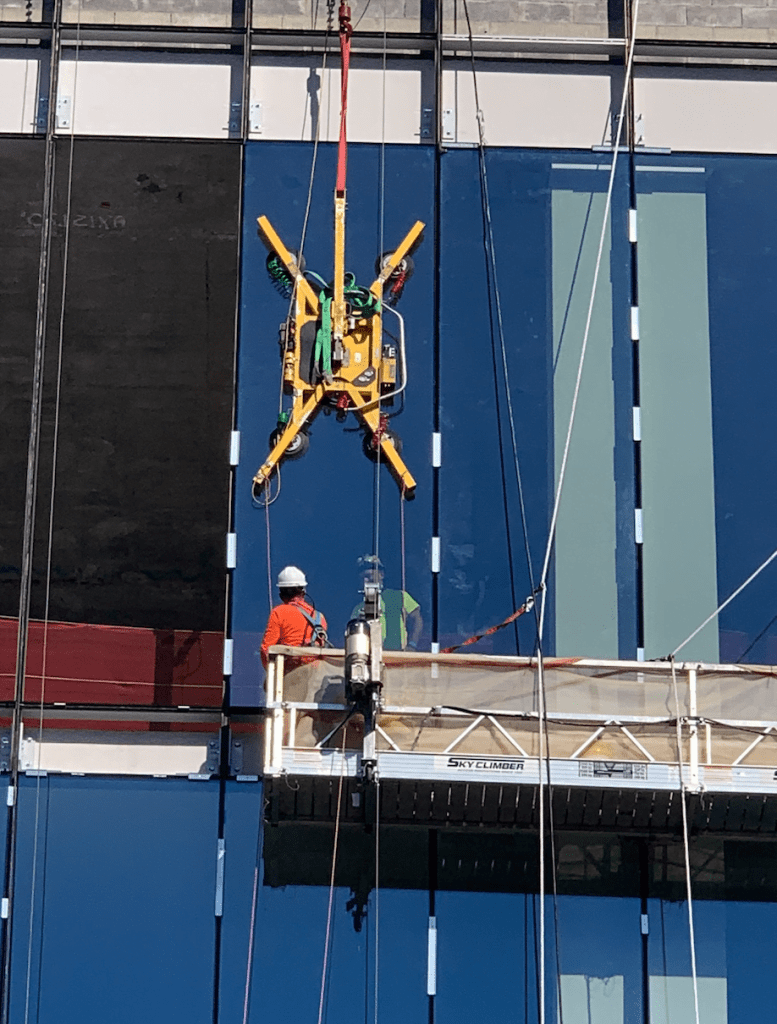

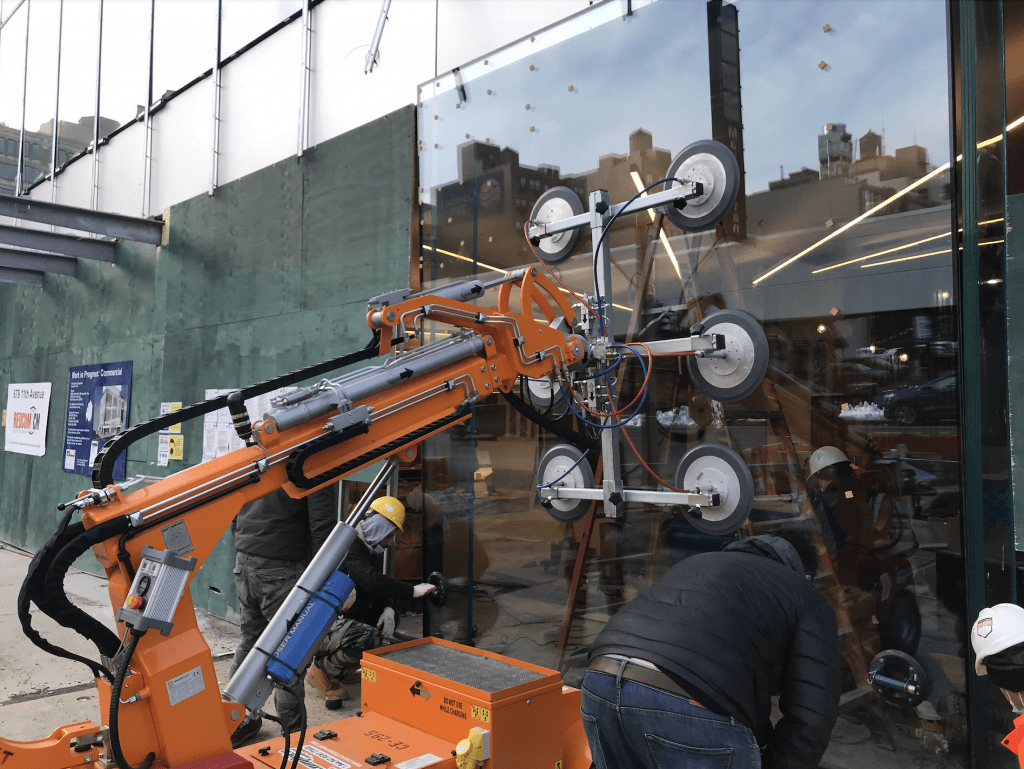

Designing and manufacturing oversized IGUs requires specialized machinery; installing them requires the use of spider cranes and manipulator. Logistics are a problem. Entire streets must be shut down to allow for trucks to pass through and unload. To do this, you must obtain permits must from the regional authorities. Only experienced companies are equipped to design and provide oversized IGUs for you. Similarly, only certified and licensed installers are equipped to handle such projects. All of our projects are handled by an external licensed and certified installation team we cooperate with.

Contact Us

If you have a project in mind and would like to learn more about your options, please contact us at 929-202-2558. Alternatively, you can email us here and someone from our team would be happy to talk you through your options.

OPEN Architectural Windows and Doors: Proudly making your architectural plans a reality for over a decade.